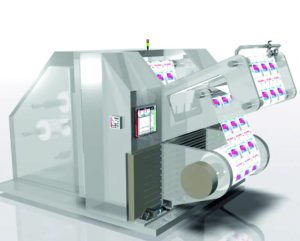

SLITTING:

STEP BY STEP TO THE PERFECT PRODUCT

Each step gets you closer to a perfect product

Whenever the web is processed, full precision makes all the difference. Flawless print results that pass quality tests in every respect are a requirement for further processing with perfect results.

Manufacturers must be able to rely on precision. For instance, webs have to be accurately fed to the slitting equipment, print defects must be steadily displayed and perforation positions must be reliably identified.

Your benefits at a glance

- Easy operation

- Convenient set-up

- Precise web guidance

- Reliable defect detection

- Exact position detection

- Effective customer service

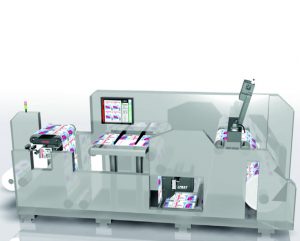

REWINDER:

RELIABILITY THAT ENSURES CUSTOMER SATISFACTION

Reliability that will pay off and contribute to customer satisfaction

A continuous workflow is an essence for working profitably. What really matters: The finished print product must feature perfect quality.

Shorter jobs increase the need to reduce set-up times to a minimum. Furthermore, manufacturers have to stop the processed web frequently (e.g., on doctoring machines).

In many cases, several processes are performed on one machine. In addition workflow, complexity is increased by the chase and follows applications as well as special variants, which are required for specific projects. All these requirements can only be met using dependable and versatile quality assurance systems.

Your benefits at a glance

- Easy operation

- Convenient set-up

- Precise web guidance

- Reliable defect detection

- Exact position detection

- Effective customer service