BST GUIDING DEVICES:

PRECISE WEB GUIDING CORRECTIONS FOR EVERY USE

BST Guiding Devices correct the position of the web precisely and almost instantaneously. In doing so, they play a central role in the smooth functioning of web guiding processes. If the actual position measured by the controller deviates from its target position, the guiding device, moved by the actuator, corrects the position until the target position is reached again.

Deliverable in various sizes and types for almost all web widths and areas of application. A number of roller designs and coatings are available for various types of material.

Our solutions result from detailed discussions with you. Already in the planning and development phases, we are at your side to provide knowledgeable support in all decisions.

Your benefit: Tailor-made systems whose performance you can rely on every time you use them.

ECO-GUIDE: THE ECONOMIC BASIS FOR YOUR WEB GUIDING

BST Eco-Guide is ideally suited for the web guiding of narrow webs. The packaging and nonwoven industries are two of its most common areas of application.

With three different sizes and various specifications, the Eco-Guide is individually configurable and extremely efficient in its use. Through its compact design and the built-in controller, installation of the system can be carried out easily, even in small spaces.

Another significant advantage of the Eco-Guide is its intuitive operation, which takes place via an ergonomic keyboard and allows for direct access to all important control functions. The maintenance-free, brushless drive allows for efficient operation, even in extreme conditions.

Eco-Guide is delivered ready for connection, keeping installation and wiring efforts to a minimum. It can be used with all installation positions and wire threading.

Eco-Guide System Equipment:

• Compatible with all digital standard edge sensors (optical or ultrasonic)

• Selectable control side

• Regulation by web edge

• Manual sensor adjustment

• Remote operation via digital inputs (digital I/O)

COMPACT-GUIDE: PRECISE WEB GUIDING, EVEN IN SMALL SPACES

BST Compact-Guide for compact web guiding is highly suitable for use in narrow webs, especially in the label, packaging, and non-woven industries.

With six different sizes, the Compact-Guide can be optimally adjusted to your requirements. Its compact, modular shape and the integrated controller allow for problem-free installation, even in small spaces. The removable, ergonomic keyboard allows for easy and intuitive operation, and for fast, direct access to all important control functions. The ready-to-connect construction minimizes the effort for installation and wiring.

Compact-Guide is implementable for all installation positions and wire threading.

Compact-Guide System Equipment:

• Compatible with all standard edge sensors (optical or ultrasonic)

• Selectable control side

• Regulation by web edge

• Manual sensor adjustment

• Remote operation via digital inputs (digital I/O)

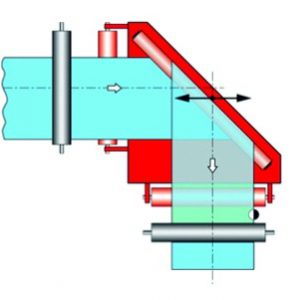

SMART-GUIDE.DF: TRIED AND TESTED SOLUTIONS FOR OPTIMAL WEB GUIDING

The main areas of implementation for the SmartGuide.DF are the printing and extrusion branches. BST eltromat rotating frame guide (DF) is also well suited for short control loops with low material demands.

For ease of operation, the sensors can be moved by optional motor-driven sensor adjustment. This is especially beneficial for the sensors that are difficult to move, web widths that frequently change, or special functions, like oscillation.

Smart-Guide.DF System Equipment:

• Compatible with all standard edge sensors (optical or ultrasonic)

• Selectable control side

• Regulation by web edge

• Manual sensor adjustment

• Remote operation via digital inputs (digital I/O)

SMART-GUIDE.WF: PRECISE WINDING THROUGH EXACT POSITION CONTROL

BST Smart-Guide.WF is frequently used in converting applications. The regulated winding and unwinding ensures the precise comparison between shifts in the web position and effectively minimizes the potential for defects.

Tried and tested BST system components and a range of options provide solutions that are optimal for customers, at a reasonable price. For example, line and contrast control is optionally available with the BST CLS Pro 600.

The Smart-Guide.WF’s modular construction facilitates subsequent, cost-effective changes at any time. The predefinition of characteristics simplifies technical clarification processes and increases transparency.

Smart-Guide.WF System Equipment:

• All standard edge sensors implementable (optical or ultrasonic)

• Regulation by web edge

• Manual sensor adjustment

• Remote control via digital inputs (digital I/O)

SPECIAL APPLICATIONS FOR WEB GUIDING: CONTROL SYSTEMS FOR EVERY DEGREE OF PROCESSING

The best arrangement of the production line depends on the web’s degree of processing:

Untreated webs are exclusively adjustable based on the web edge or web centre line because no additional contrast characteristics exist on the web itself.

In contrast, finished webs offer more options for sensory position monitoring, such as through printed lines or freely selectable contrasts.

The following information is important for the set-up of BST Web Guiding systems with a rotating frame guide or swivel-roll guide.

SWIVEL ROLL GUIDE (SF)

BST Swivel Roll guide is made-up of a fixed lower frame and a movable upper frame with one or two casters. The functional principle of this guiding device necessitates sufficiently long infeed and outfeed spans.

It is then used in the construction space is limited, and if the required web threading does not allow for the use of a rotating frame guide.

TURNING BAR

BST Turning Bar is used wherever a 90° turn in the web with simultaneous positioning of the web is necessary.

It is installed at a 45° angle for the in-feed and out-feed spans of the web. The web winds itself around the turning back at an angle of 180° and leaves the guiding device at a right angle to the entry position.