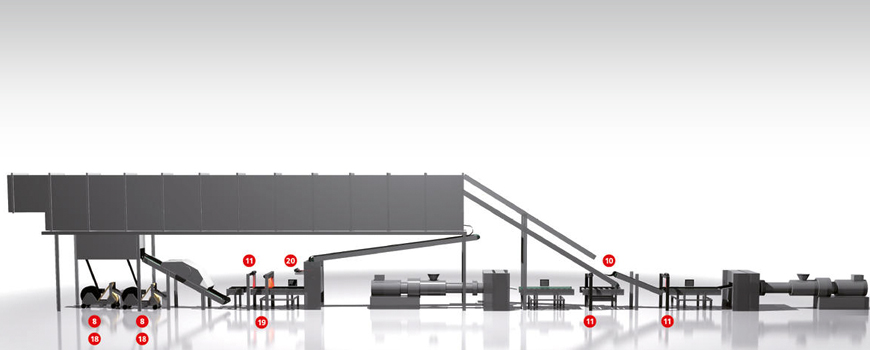

INNERLINER CALENDER LINES

With winder guiding components, web width measuring and web tension control systems, laser markers, and edge cutting positioning systems, BST eltromat helps to ensure consistent material quality.

Customer-specific and product-related solutions for material doubling or pre-assembling processes increase production efficiency.

WINDER GUIDING SYSTEM

The SmartGuide.WF ensures the controlled unwinding and rewinding of material and liner. A large range of proven components, such as controllers and actuators, facilitate adjustments for specific tasks.

DOUBLING

Depending of the tire design, BST eltromat provides individual doubling solutions based on tried and tested components and guiding technologies and the high-performance camera CCD CAM 100.

WEB WIDTH MEASURING

This system measures the widths of material in reflecting or transmitting-light mode. The high-performance camera CCD CAM 100 facilitates high precision.

WEB TENSION MEASURING SYSTEMS

The BTL Load 100-500 cells control the tensions of the rubber material and the textile cord during their run through the calender line and the web and the liner at the winder.

LASER MARKER

Guided by defined recipe data, the LASERMarker 1000 indicates the correct edge position of the web.

EDGE CUTTING POSITIONING SYSTEM

The system precisely positions the trim knife in relation to the web edges of the cut material.