INSPECTION WORKFLOW FOR TUBESCAN

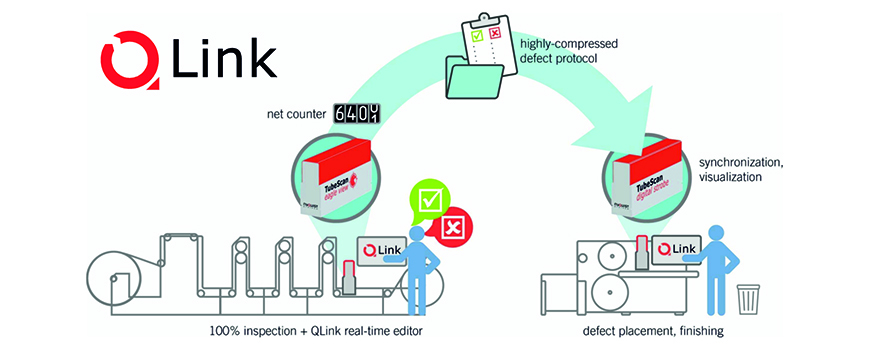

BST eltromat has expanded the TubeScan product portfolio with the new QLink Workflow, and has concentrated on synchronization, data handling and error editing. With QLink, TubeScan systems can be used for the automatic control of cutting machines and stand-alone 100% inspection systems.

Q-Link PRESS on printing press:

- Local high speed SSD data storage using latest technology

- Jobs accessible via LAN

- Highly compressed defect data to save on disk space

- Real-time roll map editing using QLink Editor

- Existing TubeScan system can be easily upgraded

Q-Link REWINDER on finishing machine:

- Select sealed roll from network

- Use local camera (QLink ICS) for synchronization and secondary inspection (no label or mark sensor required)

- Generate final roll report

- Existing TubeScan system can be easily upgraded

Your Benefits:

In comparison to previous inspection workflow systems, the cost for QLink workflow is significantly lower.

On the printing press:

- The QLink real-time editor enables you to evaluate defects already during the printing process. The printercan classify the defects as “not relevant” or “to be fixed”in the converting process.

- Larger defect areas, such as missing ink, can be definedas waste zones. These can afterwards be removed onthe rewinder in one single step.

- The net count is automatically updated after eachediting. No more costly over-production just to makesure there is enough good material.

- Through innovative compression, the file size of theprotocols is as low as 10% of the usual roll protocols(JPEG / BMP). This saves disk space and expensesand it will speed up your data transfer.

On the rewinder:

- The camera-based synchronization is easy to set-up and very reliable – in contrast to the sensor-basedsystems that are commonly used.