TUBESCAN:

PRINT INSPECTIONS SOLVED INTELLIGENTLY

Quality control during printing or finishing has to be simple and must be very reliable. At the end, your reputation depends on the work you deliver to your customers.

The concept of TubeScan sets a new standard with the smart combination of imaging technology and the stroboscopic principle.

TubeScan provides considerably higher process reliability with the base function digital strobe because it always delivers a steady image and true colour representation – independent from the machine speed.

The function of digital strobe+ is not only accurately counting repeats, labels and missing labels in total and per lane, but it also detects matrix residues across the entire web width.

By choosing the additional option digital strobe++ TubeScan even becomes a full-grown print inspection system, which is able to detect print defects and register variations below one millimetre.

Features

- Min. defect size: Approx. 0.2 mm

- Detection of fine print defects, register defects & color variations

- Web width: up to 660 mm (26″)

- Camera Resolution: 1280 pixels area scan camera with an X Direction

- Substrates: Suitable for transparent and opaque materials

- Max web speed: 250 mtrs. / min.

- Accurate counting of repeats, labels and missing labels for up to 20 lanes

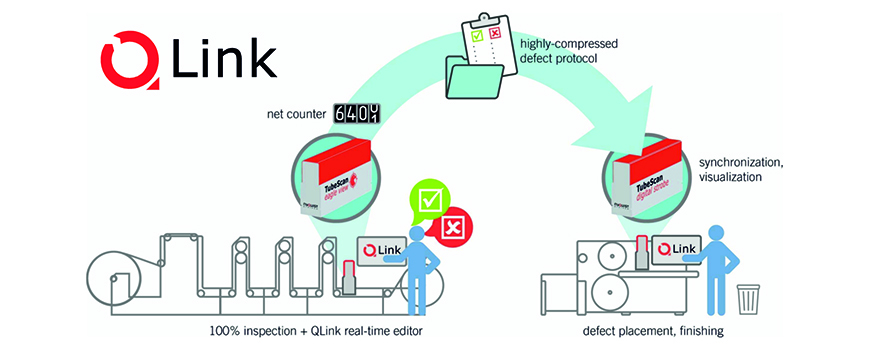

INSPECTION WORKFLOW FOR TUBESCAN

BST eltromat has expanded the TubeScan product portfolio with the new QLink Workflow, and has concentrated on synchronization, data handling and error editing. With QLink, TubeScan systems can be used for the automatic control of cutting machines and stand-alone 100% inspection systems.

Q-Link PRESS on printing press:

- Local high speed SSD data storage using latest technology

- Jobs accessible via LAN

- Highly compressed defect data to save on disk space

- Real-time roll map editing using QLink Editor

- Existing TubeScan system can be easily upgraded

Q-Link REWINDER on finishing machine:

- Select sealed roll from network

- Use local camera (QLink ICS) for synchronization and secondary inspection (no label or mark sensor required)

- Generate final roll report

- Existing TubeScan system can be easily upgraded

Your Benefits:

In comparison to previous inspection workflow systems, the cost for QLink workflow is significantly lower.

On the printing press:

- The QLink real-time editor enables you to evaluate defects already during the printing process. The printercan classify the defects as “not relevant” or “to be fixed”in the converting process.

- Larger defect areas, such as missing ink, can be definedas waste zones. These can afterwards be removed onthe rewinder in one single step.

- The net count is automatically updated after eachediting. No more costly over-production just to makesure there is enough good material.

- Through innovative compression, the file size of theprotocols is as low as 10% of the usual roll protocols(JPEG / BMP). This saves disk space and expensesand it will speed up your data transfer.

On the rewinder:

- The camera-based synchronization is easy to set-up and very reliable – in contrast to the sensor-basedsystems that are commonly used.